Services

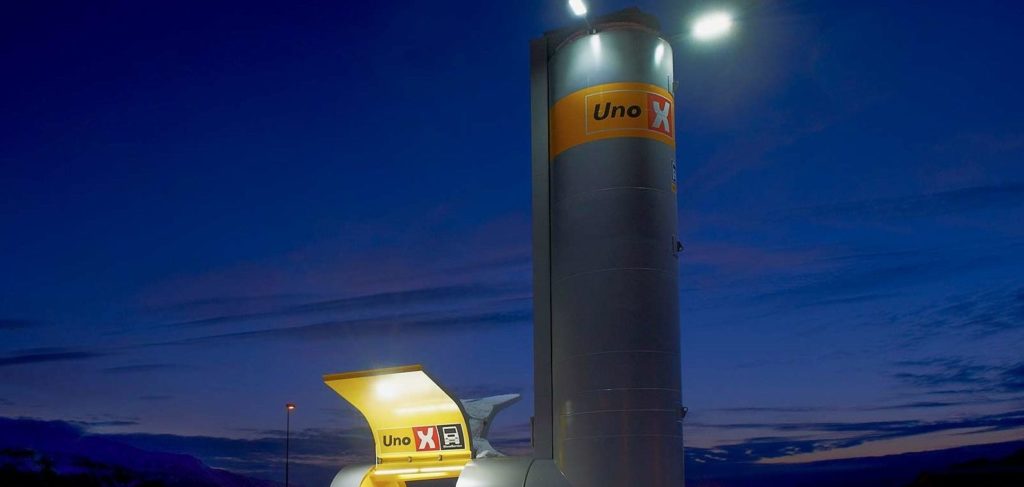

Our service process encompasses the implementation of a tank or distribution facility from the refinement of the business idea, through design, productization, factory production, and assembly, to installation – providing efficient, smart, and green solutions for liquid distribution, storage, and energy production.

Our process

Concept development

In the concept development we will develop and manufacture your business dream to productized and finished product.

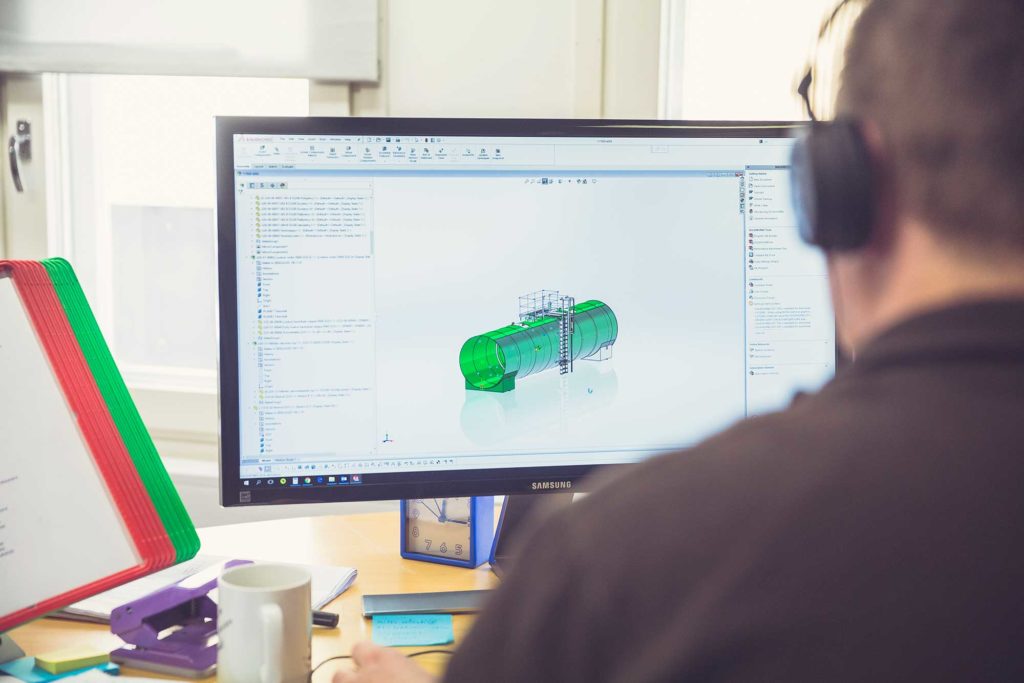

Design

Our design process always starts with 3D models, which provide the best possible solution for your needs. 3D modeling reduces errors and gives a completely different look to the quality of the documents. We design tanks and everything related to them – such as piping, steel structures, electrical systems, and control systems.

Production

Our production principle is to build the entire system into modules as complete as possible at the factory. This way, we save our customers time and money.

Installation service

A well-designed system culminates in careful and precise installation, in which we have extensive experience. Our installation and assembly teams have gained experience in various challenging environments, including underground installations at depths of 500 meters, complex piping installations, and mining installations.

Maintenance service

The value of a product is highlighted throughout its life cycle. The worry-free years of use for distribution stations, various tanks, and fuel systems are ensured by well-executed regular maintenance. The value of a well-maintained product is preserved, whereas the value of poorly maintained equipment can even become negative.

Read more

CONTACT

© 2017 U-Cont. Rekisteri- ja evästeseloste.

Suunnittelu ja toteutus Aava & Bang