Planning the construction of a distribution station.

U-Cont has the widest range of fuel distribution stations on the market for various needs. The choice of distribution station model, size, and structure can be made in many different ways, and there is no single correct solution.

Planning a distribution station.

Planning and choosing a distribution station has become very challenging in recent years due to the variety of options and the upheaval caused by climate change. What energy should be distributed and what is profitable? Where should the business be invested in and what does it cost?

At U-Cont, we have had to consider answers to these and many other questions in various countries, from the cold of Antarctica to the congestion of large cities, and to many other different customer needs, from small boat stations on Lake Saimaa to refueling giant mining monsters.

We have chosen a broad and flexible product range and a modular design approach, which allows us to combine standard solutions with highly demanding customer customizations.

We also offer solutions for a very wide range of different fuels. Next are our insights on the design and operation of distribution stations.

Location and profitability

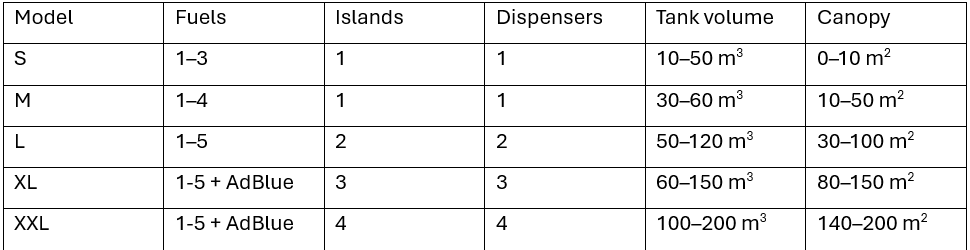

The choice of station size and business model depends entirely on the opportunities of the location. When selecting a solution, the current traffic situation and future developments must be considered. We use size categories S-XXL to express station sizes. However, the limits of these size categories are flexible.

The smallest distribution stations can be placed in an area of approximately 100 square meters plus access roads. The maximum space required for an XXL model station, excluding access areas, is about 1000 square meters. For tight plots, we recommend either the underground U-Cont or the above-ground U-Tower solution, as these take up the least space. Our standard solutions are designed to minimize space requirements. Based on experience, dispersing the equipment also increases construction and maintenance costs.

The traffic connections for a distribution station must usually be designed to accommodate trucks or at least heavy vehicles, even if the primary use is for smaller vehicles. Special consideration must be given to fuel delivery tankers to ensure they can move and distribute fuel safely. Other infrastructure connections, such as electricity, sewage, and water affect costs, but these are generally not problems along the roads.

The recommended option in groundwater areas is to build above ground. However, if underground construction is the only option, it must be done with significantly heavier protective structures, as outlined in standard SFS 3352 (groundwater areas). The same requirements apply to above-ground solutions, but they are less expensive.

The quality of the soil at the construction site significantly affects the construction costs of the station. If the soil quality is uncertain, we recommend soil investigations. For example, unstable soil, poorly bearing clay layers, or flowing water can particularly increase the costs of underground structures.

When planning a distribution station, it is important to consider the people living nearby who might be affected by the station’s operations.

Volume and its development

The choice of distribution station size is influenced by the annual sales volume, which, together with the fuel logistics location, also determines the size of the tanks. Therefore, it is advisable to choose relatively larger tanks for remote locations than near the refinery. In addition to sales volume, the number of dispensers and islands is also influenced by the customer visit behavior profile. For example, if the sales location is busy on weekends, this should be considered in the number of dispensers, but the tanks may still suffice with smaller volumes.

Typically, the tank capacity of a distribution station is sized to meet about a week’s demand for the best-selling fuels. The dispenser/island capacity is designed to ensure that there are no fueling queues under normal conditions. Below are some examples of different models

All our underground and above-ground station models can be implemented in S-XXL size categories. If the need exceeds the XXL size category and the station’s tank volume is over 200m³, a more stringent permit process is required.

Typical annual sales volumes: S under 1 million liters/year, M 0.5–1.5 million liters/year, L 1-3 million liters/year, XL 3-6 million liters/year, and XXL 5-10 million liters/year. There can be significant deviations from these amounts based on the sales profile and location.

Distributable Fuels Now and in the Future

At U-Cont distribution stations, all pipelines are usually made of stainless steel or, in special cases, ethanol-resistant plastic for underground use. We do not recommend galvanized pipes because zinc reacts with many current and future fuels or additives such as ethanol and MTBE. At U-Cont’s distribution stations, with standard solutions, they can store gasoline, diesel, ethanol blend fuels up to E20, and with minor modifications, E85 ethanol blends. AdBlue requires its own specially coated tank and special piping and pumping.

Future gas options can also be prepared for during the design and construction phase of a new station. We install gas equipment in Poland, and if necessary, it can be delivered to Finland as well.

Additionally, hydrogen refueling can be integrated into the distribution station, but this still requires auxiliary equipment and modifications, which currently increase the station’s cost. We have been involved in building hydrogen refueling stations in Norway.

Charging points for electric cars should be placed outside the refueling area for other fuels, which is also sensible from a business perspective due to their slow “refueling time.” We believe that fast charging points for electric cars with a power of over 50kW will be a reasonable business at service stations, as customers are likely to spend money on services during the “refueling” time. Charging points with a power of less than 50kW are, in our opinion, too slow and inconvenient for customers. When charging electric cars, it is important to be cautious due to the relatively high risk of sparks and fire, so placing them next to buildings or near fuel distribution should be avoided.

The area’s infrastructure and its consideration

The first thing to consider regarding the area is the zoning plan and whether it allows for fuel distribution. If not, it is advisable to start discussions with the authorities

A distribution station must not be built on, under, or next to existing infrastructure such as water pipes, sewers, high-voltage electrical cables, etc. There are safety distances for all of these, which can be found in standard 3352.

Old structures, such as large rocks and bedrock, must also be considered, as well as their impact on the distribution station solution and its costs

If there are cost-related issues underground, it is always advisable to first explore above-ground options. For above-ground gasoline storage in special tanks, we expect the government to grant permission during the winter of 2020

Visual requirements

If you want the distribution station to be as visible and distinctive as possible, we recommend choosing the U-Tower model. If you prefer a solution where the distribution is an inconspicuous part of the business, the choice is the underground U-Cont solution. The U-Tube model is a conventional version of an above-ground distribution station with a round tank. The U-Cube version, on the other hand, offers the possibility to customize the appearance of the distribution station almost infinitely with large wall surfaces and variable facade materials.

When it comes to visual design solutions, the only limit is your imagination. We offer a wide range of different materials, colors, and various enhancement techniques, including lighting or illuminated signs.

Is energy stored underground or above ground?

There is no single correct solution to this question. The national permit issue for above-ground gasoline storage has been under consideration by various administrative levels for a decade, so in the short term, gasoline storage will still be done underground. Currently, there is permission to build above-ground solutions for boat refueling and defense forces, including gasoline. We are expecting a comprehensive decision on all construction soon.

Based on our extensive international experience, we have formed an understanding of the issue of underground versus above-ground storage. However, the final decision always depends first on permits, then on network considerations, and finally on the specific site decision.

Here are some practical examples based on experience:

-In city centers and densely populated areas -> Usually underground

-In sparsely populated, rural, and industrial areas -> Usually above ground

-In groundwater areas -> Primarily above ground and only underground in extremely compelling cases

-High visibility requirement -> Above ground with the U-Tower solution

-Short operation or lease time, or expected technical changes in the future -> Above ground

-Tight or expensive plot -> Underground or U-Tower

-Difficult or unstable ground -> Above ground

-Boat refueling or high water level underground -> Above ground

Safety and authority requirements

In the design of distribution stations, safety is always the highest priority. There are many aspects of safety that must be considered. First come fire and explosion safety, and in addition to these, the requirement for soil contamination prevention, minimizing climate emissions, and ensuring traffic and movement safety must be taken into account. All of this requires good site planning. We offer both standard station site planning and fully customized solutions for our clients.

It is generally advisable to enlist the help of a consultant specialized in these projects for the permit process of a distribution station. The most common practice nowadays is to use a standard plan as a base, which is updated for the site with ready-made modules, and on which the permit process with the authorities is based. There is very rarely a need for fully customized design for the permit process. Discussions with the authorities should begin as early as possible when planning the construction of a distribution station.

Summary

It is advisable to design the distribution station to be as flexible as possible to accommodate future changing needs. The introduction of entirely new low-emission fuels, gases, and electricity to the market must also be considered from the outset. The fragmentation of the market and new solutions, whose full impacts cannot be predicted, require extensive expertise and experience in designing technical solutions.

As a business, liquid and gaseous fuel distribution stations will be needed in various forms even after the emergence of a carbon-free society. Electric vehicle solutions are becoming more common, but the winning solution is not yet known, and likely won’t be before the 2030s. Additionally, it is even probable that the future will be multi-energy based. In this situation, U-Cont has chosen a strategy of recommending flexibility to its customers, which our wide range of products best represents.

© 2017 U-Cont. Rekisteri- ja evästeseloste.

Suunnittelu ja toteutus Aava & Bang